Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

2025-03-30

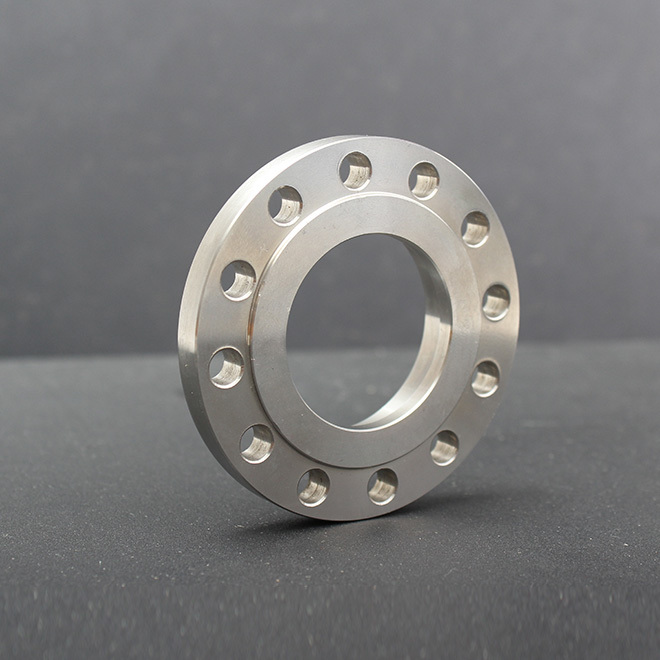

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making it suitable for high-pressure applications.

One of the primary benefits of butt welding is the seamless connection it creates, which minimizes the risk of leaks and ensures a robust bond that can withstand extreme pressures and temperatures. This quality makes butt welding pipe fittings ideal for critical applications in industries such as oil and gas, chemical processing, and water supply systems.

When working with butt welding pipe fittings, it's essential to choose the right material to match the specific requirements of your project. Common materials used include carbon steel, stainless steel, and various alloys, each offering different levels of corrosion resistance, strength, and durability. Understanding these materials' properties is vital for ensuring the longevity and safety of the installed piping system.

Another critical aspect of butt welding is the preparation of the pipe ends before welding. Proper cleaning and alignment are essential to achieve a strong, defect-free weld. The surfaces must be free of contaminants like rust, dirt, and oil, and should be aligned accurately to avoid misalignment during welding. Professionals often use tools such as pipe cutters, grinders, and alignment clamps to achieve the best results.

In addition to preparation, the welding process itself requires skilled workmanship. Techniques such as preheating the pipe ends and using the correct welding parameters are crucial for achieving optimal joint strength. Advanced welding methods, including automatic and semi-automatic processes, can enhance efficiency and consistency, especially in large-scale projects.

Moreover, post-weld inspections are a standard practice to ensure the quality of the weld. Techniques like non-destructive testing (NDT) can identify any defects that may compromise the integrity of the joint. This step is essential in maintaining the safety and reliability of the entire piping system.

In conclusion, butt welding pipe fittings play a pivotal role in ensuring effective and efficient piping systems in the construction and decorative materials industry. By understanding the benefits, preparation methods, and welding techniques, professionals can ensure high-quality installations that meet industry standards and client expectations. Whether you are involved in installation or maintenance, keeping these factors in mind will enhance your project outcomes and ensure lasting performance.

One of the primary benefits of butt welding is the seamless connection it creates, which minimizes the risk of leaks and ensures a robust bond that can withstand extreme pressures and temperatures. This quality makes butt welding pipe fittings ideal for critical applications in industries such as oil and gas, chemical processing, and water supply systems.

When working with butt welding pipe fittings, it's essential to choose the right material to match the specific requirements of your project. Common materials used include carbon steel, stainless steel, and various alloys, each offering different levels of corrosion resistance, strength, and durability. Understanding these materials' properties is vital for ensuring the longevity and safety of the installed piping system.

Another critical aspect of butt welding is the preparation of the pipe ends before welding. Proper cleaning and alignment are essential to achieve a strong, defect-free weld. The surfaces must be free of contaminants like rust, dirt, and oil, and should be aligned accurately to avoid misalignment during welding. Professionals often use tools such as pipe cutters, grinders, and alignment clamps to achieve the best results.

In addition to preparation, the welding process itself requires skilled workmanship. Techniques such as preheating the pipe ends and using the correct welding parameters are crucial for achieving optimal joint strength. Advanced welding methods, including automatic and semi-automatic processes, can enhance efficiency and consistency, especially in large-scale projects.

Moreover, post-weld inspections are a standard practice to ensure the quality of the weld. Techniques like non-destructive testing (NDT) can identify any defects that may compromise the integrity of the joint. This step is essential in maintaining the safety and reliability of the entire piping system.

In conclusion, butt welding pipe fittings play a pivotal role in ensuring effective and efficient piping systems in the construction and decorative materials industry. By understanding the benefits, preparation methods, and welding techniques, professionals can ensure high-quality installations that meet industry standards and client expectations. Whether you are involved in installation or maintenance, keeping these factors in mind will enhance your project outcomes and ensure lasting performance.

butt welding pipe fittings

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

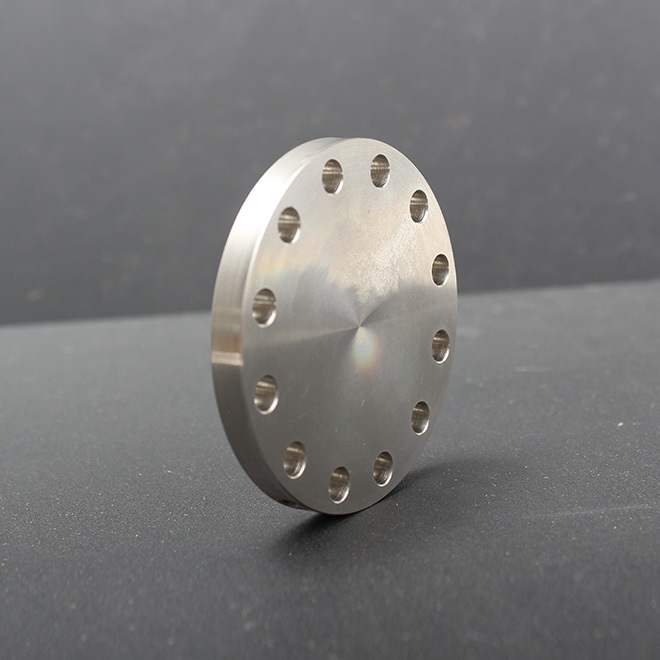

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30