Efficiency Redefined: The Impact of 90 Degree Elbows on Pipe Network Optimization

2025-03-27

Efficiency Redefined: The Impact of 90 Degree Elbows on Pipe Network Optimization

Table of Contents

1. Introduction to Pipe Networks and Elbows

2. Understanding 90 Degree Elbows

3. The Importance of Optimization in Pipe Networks

4. Benefits of Using 90 Degree Elbows in Pipe Systems

5. Engineering Considerations for 90 Degree Elbows

6. Best Practices for Installing 90 Degree Elbows

7

Efficiency Redefined: The Impact of 90 Degree Elbows on Pipe Network Optimization

Table of Contents

- 1. Introduction to Pipe Networks and Elbows

- 2. Understanding 90 Degree Elbows

- 3. The Importance of Optimization in Pipe Networks

- 4. Benefits of Using 90 Degree Elbows in Pipe Systems

- 5. Engineering Considerations for 90 Degree Elbows

- 6. Best Practices for Installing 90 Degree Elbows

- 7. Maintenance and Inspection of Elbows in Pipe Networks

- 8. Case Studies: Real-World Applications of 90 Degree Elbows

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Pipe Networks and Elbows

In the realm of plumbing and construction, the efficiency of a pipe network can significantly impact overall performance and cost-effectiveness. As engineers and contractors look for ways to optimize these systems, one crucial component comes into play: the **90-degree elbow**. This article explores the role of 90-degree elbows in pipe network optimization, shedding light on their functionality, advantages, and best practices for installation and maintenance.

2. Understanding 90 Degree Elbows

A 90-degree elbow is a type of pipe fitting that allows for a **change in direction** at a right angle within a piping system. Often made from materials such as PVC, stainless steel, or copper, these fittings help direct fluid flow while minimizing turbulence. Understanding the technical specifications of 90-degree elbows is essential for effective system design and application.

2.1 Types of 90 Degree Elbows

There are several types of 90-degree elbows, each suited for different applications:

- **Short Radius Elbows:** Suitable for tight spaces, these elbows require less linear space but may increase pressure loss.

- **Long Radius Elbows:** Providing a smoother transition, long radius elbows are ideal for minimizing turbulence and maintaining flow rates.

2.2 Material Composition

The choice of material for 90-degree elbows can influence durability and performance. Common materials include:

- **PVC:** Lightweight and corrosion-resistant, ideal for residential plumbing.

- **Stainless Steel:** Offers durability and resistance to high temperatures, suitable for industrial applications.

- **Copper:** Excellent for high-pressure systems but may be more expensive.

3. The Importance of Optimization in Pipe Networks

Optimization in pipe networks is critical for enhancing fluid flow, reducing energy consumption, and minimizing maintenance costs. By strategically implementing fittings like **90-degree elbows**, engineers can create a more efficient system that meets operational demands without incurring excessive costs.

3.1 Energy Efficiency

Optimizing fluid flow through careful design reduces the energy required to pump materials through the system. This leads to lower operating costs and decreased wear on pumps.

3.2 Reduced Maintenance Costs

A well-optimized pipe network experiences fewer blockages and maintenance issues, which translates to cost savings and increased reliability.

4. Benefits of Using 90 Degree Elbows in Pipe Systems

Integrating 90-degree elbows into a pipe network offers numerous benefits that enhance overall system performance.

4.1 Improved Flow Efficiency

90-degree elbows facilitate smoother transitions, which leads to improved flow efficiency. By minimizing sharp turns, these fittings help reduce turbulence, allowing liquids or gases to flow more freely.

4.2 Space-Saving Design

In many construction scenarios, space is at a premium. The use of 90-degree elbows can help designers save precious linear space by changing direction without requiring extensive piping runs.

4.3 Versatility in Applications

From residential plumbing to large industrial systems, 90-degree elbows find application in a wide range of industries, enabling flexibility in design and implementation.

5. Engineering Considerations for 90 Degree Elbows

When designing a pipe network that includes 90-degree elbows, several engineering considerations should be taken into account.

5.1 Flow Rate and Pressure Drop

Engineers must calculate the expected flow rate and associated pressure drops when incorporating elbows into the design. Tools and software are available to simulate these conditions and make informed decisions.

5.2 Material Selection Based on Application

Choosing the appropriate material for elbows based on the specific application is crucial. Factors such as temperature, pressure, and fluid composition must be considered to ensure durability and performance.

6. Best Practices for Installing 90 Degree Elbows

The installation of 90-degree elbows must be executed with precision to ensure optimal performance.

6.1 Proper Alignment

Ensuring that the elbow is aligned correctly with the pipe is essential. Misalignment can lead to increased wear and tear, as well as compromised flow efficiency.

6.2 Using Appropriate Sealants

When connecting 90-degree elbows, use suitable sealants or welding techniques to prevent leaks. Inadequate sealing can lead to fluid loss and pressure variations in the system.

6.3 Following Manufacturer Guidelines

Always adhere to manufacturer instructions and guidelines for installation. This ensures that the elbows function as intended and maintain structural integrity.

7. Maintenance and Inspection of Elbows in Pipe Networks

Regular maintenance and inspection of 90-degree elbows are vital for ensuring long-term performance and reliability.

7.1 Routine Inspections

Conduct routine inspections to identify any signs of wear, corrosion, or leaks. Early detection can prevent significant issues down the line.

7.2 Cleaning and Maintenance Routines

Implement cleaning schedules to prevent buildup inside the elbows, which can restrict flow and lead to pressure drops. Maintenance routines should be tailored to the specific application and environmental conditions.

8. Case Studies: Real-World Applications of 90 Degree Elbows

Examining real-world examples can provide valuable insights into the practical benefits of using 90-degree elbows in various industries.

8.1 Residential Plumbing Systems

In residential plumbing, the strategic use of 90-degree elbows allows for efficient routing of water lines, improving flow rates while minimizing costs associated with excessive piping.

8.2 Industrial Manufacturing

In industrial settings, pipe networks often require complex layouts. The use of 90-degree elbows facilitates effective fluid transport, maintaining consistent flow rates and operational efficiency.

9. Frequently Asked Questions

9.1 What materials are best for 90-degree elbows?

The best materials depend on the application. Stainless steel is ideal for high-pressure systems, while PVC is suitable for residential plumbing due to its corrosion resistance and lightweight properties.

9.2 How do 90-degree elbows affect flow rate?

90-degree elbows can introduce pressure drops; however, using long radius elbows can help minimize turbulence and maintain flow efficiency.

9.3 Are there alternatives to 90-degree elbows?

Yes, alternatives include flexible hoses or other angled fittings, but these may not offer the same efficiency and durability as standard 90-degree elbows.

9.4 How often should I inspect my pipe network?

Regular inspections should be conducted at least once a year, with more frequent checks recommended in high-use or industrial settings.

9.5 What are the common installation mistakes with 90-degree elbows?

Common mistakes include misalignment and inadequate sealing, both of which can lead to leaks and reduced efficiency.

10. Conclusion

In summary, the impact of 90-degree elbows on pipe network optimization is profound. These fittings enhance flow efficiency, save space, and provide versatility across a range of applications. By adhering to best practices in design, installation, and maintenance, engineers and contractors can ensure that their pipe networks operate at peak efficiency. As we continue to explore and innovate within the construction and plumbing industries, the role of 90-degree elbows remains a cornerstone of effective pipe network management. Implementing these insights can lead to an optimized, cost-effective, and reliable piping solution that meets the demands of any project.

90 degree elbow

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

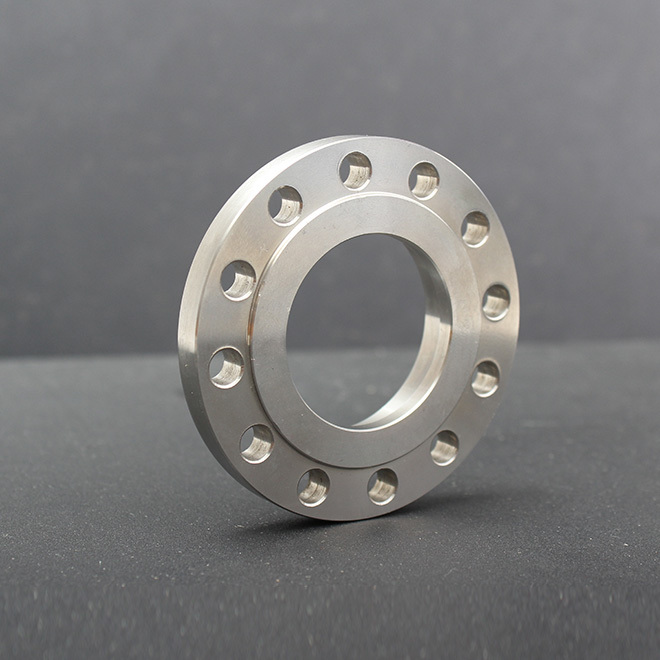

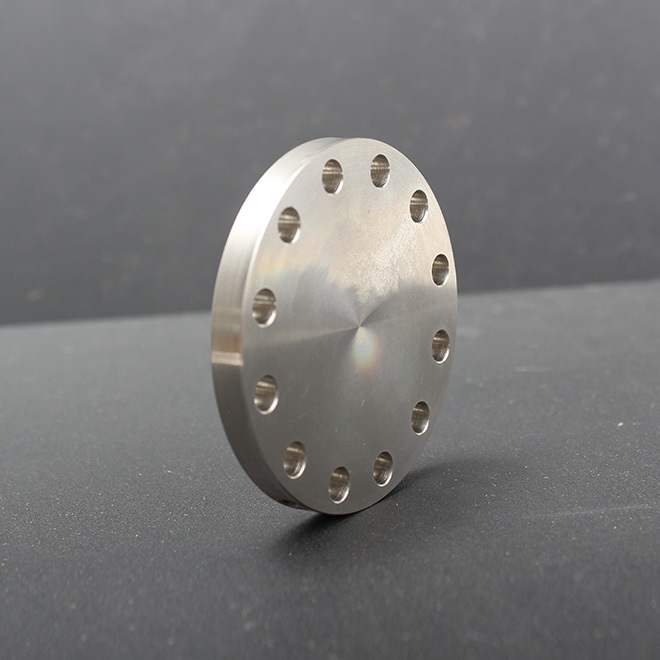

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30