Innovative Flange Solutions: Revolutionizing the Construction Industry

2025-03-09

Innovative Flange Solutions: Revolutionizing the Construction Industry

Table of Contents

1. Introduction to Flanges

2. The Importance of Flanges in Construction

3. Innovative Flange Designs

4. Material Advancements in Flange Technology

5. Applications of Flanges in Various Industries

6. The Future of Flange Solutions

7. Sustainability in Flange Manufacturing

8. Frequently Asked Qu

Innovative Flange Solutions: Revolutionizing the Construction Industry

Table of Contents

- 1. Introduction to Flanges

- 2. The Importance of Flanges in Construction

- 3. Innovative Flange Designs

- 4. Material Advancements in Flange Technology

- 5. Applications of Flanges in Various Industries

- 6. The Future of Flange Solutions

- 7. Sustainability in Flange Manufacturing

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Flanges

Flanges are essential components in piping systems, acting as connectors between pipes, valves, pumps, and other equipment. They provide a reliable and secure joint that can withstand high pressures and temperatures. As construction methods evolve, so do flange designs and materials, making them more efficient and adaptable to modern engineering needs. Understanding the fundamentals of flanges is crucial for industry professionals to leverage their benefits effectively.

2. The Importance of Flanges in Construction

Flanges play a pivotal role in ensuring the integrity and safety of construction projects. They facilitate easy assembly and disassembly of piping systems, allowing for maintenance and repairs without disrupting the entire structure. The versatility of flanges makes them suitable for various applications, including residential buildings, commercial structures, and industrial facilities. Their ability to provide leak-proof connections is critical in industries such as oil and gas, water treatment, and chemical processing.

2.1 Enhancing Structural Integrity

The reliability of flanges directly impacts the overall structural integrity of construction projects. By using high-quality flange solutions, engineers can ensure that their systems can handle the required loads and stresses. This is particularly important in high-rise buildings and complex industrial applications where safety and performance are paramount.

2.2 Cost Efficiency and Reduced Downtime

Innovative flange solutions contribute to cost savings through easier installation and maintenance. Flanges that are designed for quick assembly can significantly reduce project timelines, resulting in lower labor costs and enhanced productivity. Additionally, the ease of access to piping systems allows for faster repairs, minimizing downtime and operational disruptions.

3. Innovative Flange Designs

Recent advancements in flange designs have led to the development of innovative solutions that cater to the evolving needs of the construction industry. Here are some notable designs making waves:

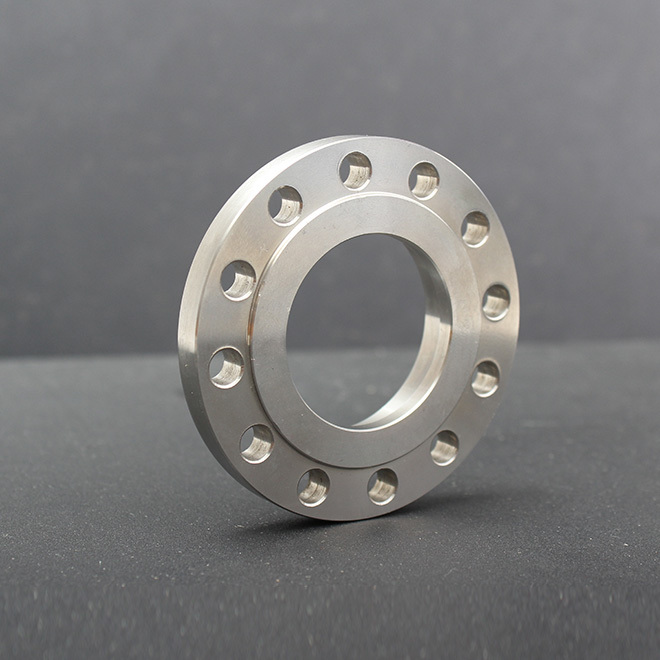

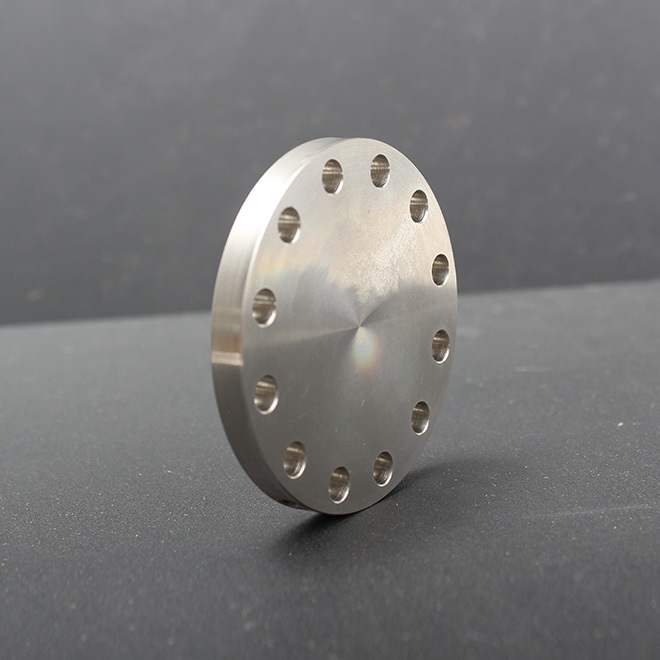

3.1 Blind Flanges

Blind flanges are used to seal the end of a piping system. They prevent the flow of fluids and gases while providing a robust sealing mechanism. These flanges are essential for testing and maintenance, ensuring that systems can be easily isolated without major interruptions.

3.2 Weld Neck Flanges

Weld neck flanges are designed for high-pressure applications and provide excellent stress distribution. Their tapered neck allows for a smooth flow of fluids, reducing turbulence and potential wear on the piping system. These flanges are commonly used in critical applications such as refineries and power plants.

3.3 Slip-on Flanges

Slip-on flanges are easy to install and are often used in low-pressure applications. They are slipped over the pipe and then welded in place, providing a strong connection without the need for complex fabrication. This design is particularly advantageous for projects where time and budget constraints are a concern.

4. Material Advancements in Flange Technology

The materials used in flange manufacturing have seen significant advancements, enhancing their performance and durability. Traditional materials such as carbon steel and stainless steel remain popular; however, new materials are emerging to meet specific industry demands.

4.1 Corrosion-Resistant Alloys

Corrosion-resistant alloys are increasingly being used in flange production, particularly in industries exposed to harsh environments. These materials ensure longevity and reduce maintenance costs, making them ideal for offshore applications and chemical processing plants.

4.2 Composite Materials

The development of composite materials has opened new avenues in flange technology. These materials offer a combination of strength and lightweight properties, making them suitable for applications where weight reduction is critical, such as aerospace and transportation.

5. Applications of Flanges in Various Industries

Flanges are utilized across a myriad of industries, each requiring specific designs and materials to meet their unique challenges. Here are some key sectors where innovative flange solutions are making a significant impact.

5.1 Oil and Gas Industry

The oil and gas industry relies heavily on flanges for connecting pipes in drilling and transportation operations. With the increasing demand for energy, advanced flange solutions are being implemented to enhance safety and efficiency in extraction and distribution processes.

5.2 Water Treatment Facilities

Flanges play a crucial role in water treatment facilities, where they are used to connect pipelines and equipment. The need for reliable, leak-proof connections is vital in ensuring the integrity of the water supply and preventing contamination.

5.3 Chemical Processing Plants

In chemical processing, flanges must withstand aggressive chemicals and high pressures. Innovative materials and designs are being used to create flanges that provide secure connections while resisting corrosion and degradation.

6. The Future of Flange Solutions

The future of flange technology looks promising, with ongoing research and development efforts focusing on enhancing performance and sustainability. Here are some anticipated trends:

6.1 Smart Flanges

As the construction industry embraces smart technology, the emergence of smart flanges is on the horizon. Equipped with sensors, these flanges can monitor pressure, temperature, and fluid levels in real-time, providing valuable data for predictive maintenance.

6.2 3D Printed Flanges

The advent of 3D printing technology is revolutionizing flange manufacturing. Customizable designs can be produced quickly and cost-effectively, enabling solutions tailored to specific project requirements. This innovation can significantly reduce lead times and material waste.

7. Sustainability in Flange Manufacturing

With a growing emphasis on sustainability in construction, the flange manufacturing industry is also making strides. Manufacturers are adopting eco-friendly practices and materials to reduce their environmental footprint.

7.1 Recycled Materials

The use of recycled materials in flange production is becoming more prevalent. By incorporating recycled metals and alloys, manufacturers can minimize resource consumption and promote a circular economy.

7.2 Energy-Efficient Production Processes

Innovative production techniques that consume less energy are being implemented in flange manufacturing. These processes not only reduce operational costs but also contribute to lower greenhouse gas emissions.

8. Frequently Asked Questions

8.1 What are flanges used for in construction?

Flanges are used to connect pipes, valves, and equipment in construction projects, providing secure and leak-proof joints that enhance system integrity.

8.2 What materials are commonly used for flanges?

Common materials include carbon steel, stainless steel, and corrosion-resistant alloys. New materials such as composites are also gaining popularity.

8.3 How do innovative flange solutions improve efficiency?

Innovative flange designs facilitate easier installation and maintenance, reducing downtime and labor costs while ensuring reliability and safety.

8.4 What industries benefit the most from flange technology?

Industries such as oil and gas, water treatment, and chemical processing heavily rely on flange technology for their operations and infrastructure.

8.5 What is the future of flange technology?

The future of flange technology includes advancements such as smart flanges equipped with sensors, as well as the use of 3D printing for customizable designs.

9. Conclusion

Innovative flange solutions are indeed revolutionizing the construction industry, providing enhanced safety, efficiency, and adaptability to meet the diverse needs of various sectors. As technology continues to advance, the potential for flanges to transform construction practices is immense. By leveraging these cutting-edge solutions, industry professionals can ensure the integrity and sustainability of their projects, setting new standards for the future of construction.

carbon steel flange

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30