Understanding Large Diameter Carbon Steel Plate Flanges: Essential Insights for Construction and Decoration

2025-03-06

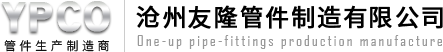

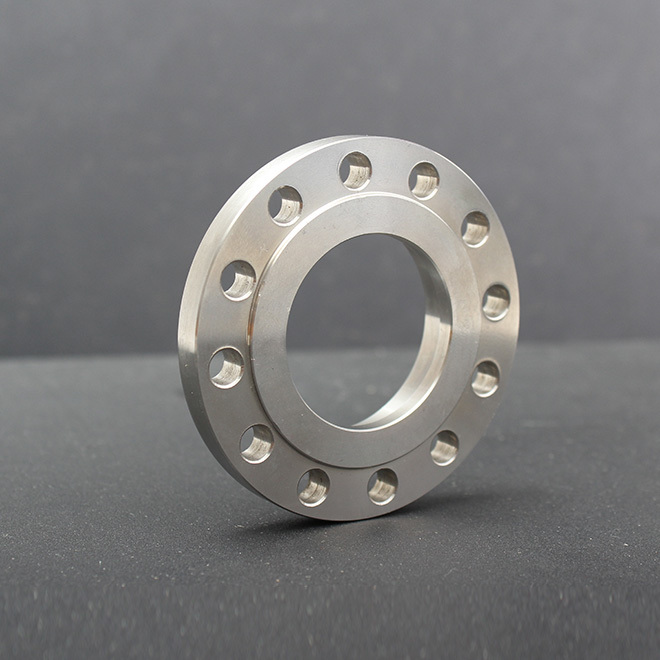

Large diameter carbon steel plate flanges are essential components in various piping systems within the construction and decoration industry. These flanges are designed to connect pipes, valves, and other equipment, ensuring a secure and leak-free assembly. Understanding their characteristics and applications can significantly enhance the efficiency and safety of your projects.

One of the primary

Large diameter carbon steel plate flanges are essential components in various piping systems within the construction and decoration industry. These flanges are designed to connect pipes, valves, and other equipment, ensuring a secure and leak-free assembly. Understanding their characteristics and applications can significantly enhance the efficiency and safety of your projects.

One of the primary advantages of large diameter carbon steel plate flanges is their strength and durability. Carbon steel is known for its high tensile strength, making it an ideal choice for applications that require robust connections under high pressure and temperature. These flanges can withstand harsh environmental conditions, making them suitable for industries such as oil and gas, chemical processing, and water treatment.

When selecting large diameter carbon steel plate flanges, it's essential to consider their dimensions and specifications. Flanges are available in various sizes, and choosing the right one depends on the pipe diameter, pressure rating, and type of connection required. Common standards for flanges include ANSI, ASME, and API, which outline the specifications for different applications. Familiarizing yourself with these standards will help ensure compliance and compatibility within your piping systems.

Another critical factor is the flange design. Large diameter flanges may come in different styles, including slip-on, weld neck, blind, and threaded. Each design serves specific purposes and offers distinct advantages. For example, weld neck flanges provide a smooth transition between the flange and pipe, reducing stress concentrations, while slip-on flanges are easier to install and require less precision during fabrication.

In addition to strength and design, the surface finish of large diameter carbon steel plate flanges plays a vital role in their performance. Proper surface preparation and treatment can prevent corrosion and extend the lifespan of the flanges. It's advisable to choose flanges that have been coated or treated with anti-corrosive materials, particularly in environments exposed to moisture or aggressive chemicals.

Installation practices are equally important when working with large diameter carbon steel plate flanges. Proper alignment, bolting techniques, and torque specifications are crucial to achieving a reliable seal. Ensuring that the flanges are installed according to industry standards will minimize the risk of leaks and failures in your piping system.

In summary, large diameter carbon steel plate flanges are indispensable in the construction and decoration industry. By understanding their properties, specifications, and installation requirements, you can enhance the safety and efficiency of your projects. Investing time in selecting the right flanges will yield significant long-term benefits, ensuring smooth operations and reduced maintenance costs in your piping systems.

One of the primary advantages of large diameter carbon steel plate flanges is their strength and durability. Carbon steel is known for its high tensile strength, making it an ideal choice for applications that require robust connections under high pressure and temperature. These flanges can withstand harsh environmental conditions, making them suitable for industries such as oil and gas, chemical processing, and water treatment.

When selecting large diameter carbon steel plate flanges, it's essential to consider their dimensions and specifications. Flanges are available in various sizes, and choosing the right one depends on the pipe diameter, pressure rating, and type of connection required. Common standards for flanges include ANSI, ASME, and API, which outline the specifications for different applications. Familiarizing yourself with these standards will help ensure compliance and compatibility within your piping systems.

Another critical factor is the flange design. Large diameter flanges may come in different styles, including slip-on, weld neck, blind, and threaded. Each design serves specific purposes and offers distinct advantages. For example, weld neck flanges provide a smooth transition between the flange and pipe, reducing stress concentrations, while slip-on flanges are easier to install and require less precision during fabrication.

In addition to strength and design, the surface finish of large diameter carbon steel plate flanges plays a vital role in their performance. Proper surface preparation and treatment can prevent corrosion and extend the lifespan of the flanges. It's advisable to choose flanges that have been coated or treated with anti-corrosive materials, particularly in environments exposed to moisture or aggressive chemicals.

Installation practices are equally important when working with large diameter carbon steel plate flanges. Proper alignment, bolting techniques, and torque specifications are crucial to achieving a reliable seal. Ensuring that the flanges are installed according to industry standards will minimize the risk of leaks and failures in your piping system.

In summary, large diameter carbon steel plate flanges are indispensable in the construction and decoration industry. By understanding their properties, specifications, and installation requirements, you can enhance the safety and efficiency of your projects. Investing time in selecting the right flanges will yield significant long-term benefits, ensuring smooth operations and reduced maintenance costs in your piping systems.

large diameter carbon steel plate flange

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30