Maximize Space Utilization with 45 Degree Elbows in Pipe Installation: A Comprehensive Guide

2025-03-21

Maximize Space Utilization with 45 Degree Elbows in Pipe Installation

In the construction and plumbing industry, effective space utilization is a priority, especially when it comes to piping systems. One innovative solution that has gained traction among professionals is the use of 45-degree elbows in pipe installation. This article explores how these fittings can significantly enhance your installation process, offering not only efficiency but also space-saving advantages.

Understanding Pipe Fittings: The Role of 45 Degree Elbows

Pipe fittings are essential components in various plumbing and construction applications, enabling smooth transitions and connections between different pipe sections. Among these fittings, the 45-degree elbow serves a unique purpose. Unlike standard 90-degree elbows, which create sharp turns that can disrupt flow, 45-degree elbows provide a gentler angle for directional changes, contributing to better flow dynamics and reduced pressure loss.

Benefits of Utilizing 45 Degree Elbows

Employing 45-degree elbows in your pipe systems offers numerous advantages that can enhance both the functionality and efficiency of your installation:

1. Improved Flow Efficiency

The gentle curve of a 45-degree elbow minimizes turbulence and pressure drops, allowing for a smoother flow of fluids. This efficiency is particularly vital in systems where maintaining optimal flow rates is crucial.

2. Space Optimization

In tight spaces, such as commercial buildings and residential areas, maximizing available square footage is essential. 45-degree elbows enable installations that require less space than traditional fittings, allowing for creative design solutions without compromising functionality.

3. Reduced Wear and Tear

With a smoother flow comes less friction and wear on the pipes and fittings. This longevity translates to lower maintenance costs and fewer replacements over time, ultimately saving money.

4. Versatility in Design

45-degree elbows can be utilized in various applications, from plumbing and HVAC systems to industrial piping. Their versatility makes them suitable for both residential and commercial projects.

5. Easier Installation

When compared to more complex fittings, 45-degree elbows offer a straightforward installation process. Their design allows for quicker connections, reducing labor time and costs.

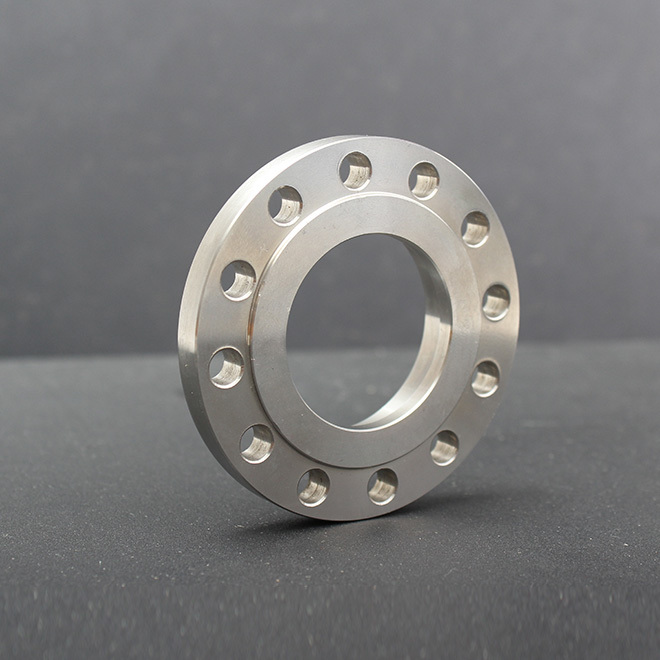

Choosing the Right Material for 45 Degree Elbows

When selecting 45-degree elbows for your project, the choice of material is critical. Various materials offer different benefits, depending on your specific requirements:

1. PVC Elbows

PVC (Polyvinyl Chloride) elbows are lightweight, corrosion-resistant, and ideal for cold water systems. They are easy to install and cost-effective, making them a popular choice for residential plumbing.

2. Copper Elbows

Copper elbows offer excellent durability and resistance to corrosion. They are suitable for both hot and cold water systems and are often used in commercial plumbing applications due to their longevity.

3. Steel Elbows

Steel 45-degree elbows are robust and capable of handling high-pressure applications. They are commonly used in industrial settings where strength and durability are paramount.

Installation Techniques for 45 Degree Elbows

Proper installation of 45-degree elbows is crucial to ensure optimal performance and longevity. Here are some essential steps to follow when incorporating these fittings into your piping system:

1. Planning Your Layout

Before installation, carefully plan your piping layout. Consider the flow direction and how the 45-degree elbows will fit into the overall design. Utilizing pipe modeling software can help visualize the layout effectively.

2. Preparing the Pipes

Clean the ends of the pipes where the elbows will be installed to ensure a secure fit. Remove any debris or contaminants that may hinder a proper connection.

3. Fitting the Elbows

Slide the 45-degree elbows onto the ends of the pipes and ensure they are aligned correctly. Depending on the material, you may need to use solvent cement for PVC or soldering techniques for copper fittings.

4. Securing the Connections

Once the elbows are fitted, secure the connections as per the manufacturer’s guidelines. This may involve using clamps or adhesives to ensure a leak-proof seal.

5. Testing the System

After installation, conduct a pressure test to ensure there are no leaks. This step is crucial, especially in systems that handle pressurized fluids.

Applications of 45 Degree Elbows in Different Industries

45-degree elbows are versatile and find applications in various industries, each benefiting from their unique advantages:

1. Residential Plumbing

In home plumbing systems, 45-degree elbows are frequently used for drainage and venting applications. They enhance flow efficiency in sinks, toilets, and showers, ensuring effective waste removal.

2. Industrial Piping

In industrial environments, the durability and strength of 45-degree steel elbows make them ideal for handling high-pressure fluids and gases, contributing to safety and efficiency.

3. HVAC Systems

In heating, ventilation, and air conditioning systems, 45-degree elbows help direct airflow efficiently through ductwork, improving climate control and energy efficiency.

4. Chemical Processing

Chemical plants often utilize PVC or stainless steel 45-degree elbows to transport corrosive materials safely. Their resistance to corrosion is vital in maintaining system integrity.

Common Mistakes to Avoid When Using 45 Degree Elbows

While 45-degree elbows offer many advantages, common installation mistakes can compromise their effectiveness. Here are some pitfalls to avoid:

1. Incorrect Sizing

Always ensure that the elbow size matches the diameter of the pipes being used. Incorrect sizing can lead to leaks and reduced flow efficiency.

2. Neglecting Support

Failing to provide adequate support for the piping can lead to stress on the elbows, potentially causing joint failures over time.

3. Ignoring Flow Direction

When installing 45-degree elbows, it is essential to maintain the correct flow direction to prevent backflow and ensure optimal performance.

4. Skipping the Pressure Test

Neglecting to perform a pressure test post-installation can lead to unnoticed leaks, resulting in costly damage and repairs later on.

Frequently Asked Questions (FAQs)

1. What are the main advantages of using 45-degree elbows over 90-degree elbows?

45-degree elbows create smoother transitions, reducing turbulence and pressure loss while also requiring less space, making them ideal for tight installations.

2. Can 45-degree elbows be used in all types of piping systems?

Yes, 45-degree elbows can be utilized in a variety of piping systems, including residential plumbing, industrial applications, and HVAC systems.

3. What materials are commonly used for 45-degree elbows?

Common materials include PVC, copper, and steel, each offering unique properties suited for different applications.

4. How do I ensure a leak-proof installation of 45-degree elbows?

Ensure proper cleaning of pipe ends, secure fitting, and use the correct adhesives or soldering methods based on the material.

5. Are there any specific maintenance tips for systems using 45-degree elbows?

Regular inspections for leaks and wear, maintaining proper support for the piping, and ensuring the elimination of blockages are key maintenance steps.

Conclusion

In conclusion, the use of 45-degree elbows in pipe installation offers significant benefits, including improved flow efficiency, space optimization, and versatility across various industries. By understanding their advantages, selecting the right materials, and following proper installation techniques, we can maximize the effectiveness of our piping systems. Whether in residential plumbing, industrial applications, or HVAC systems, incorporating 45-degree elbows is a strategic choice for achieving optimal performance and longevity in pipe installations.

45 degree elbow

RELATED NEWS

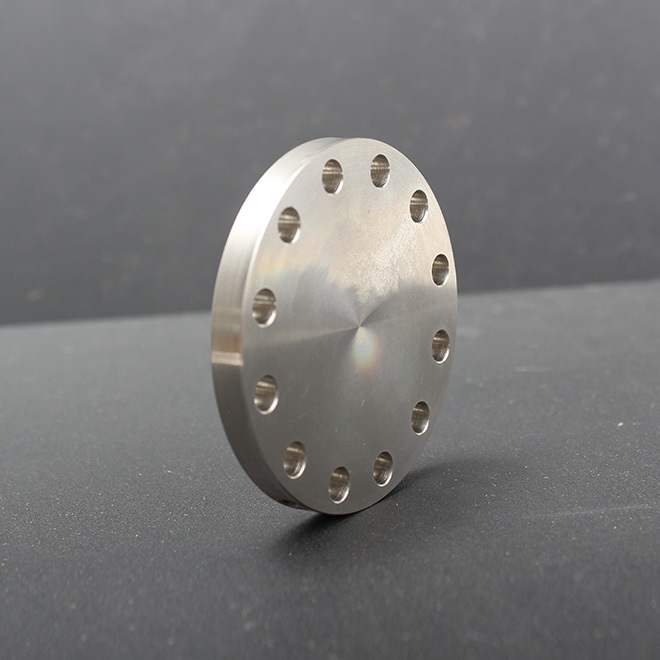

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

2025-04-05

Essential Features of Carbon Steel Blind Flanges You Should Know

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

2025-03-30