Pipe Caps: The Ultimate Protection for Flange Joints

2025-03-15

Pipe Caps: The Ultimate Protection for Flange Joints

Table of Contents

Introduction to Pipe Caps and Their Importance

Types of Pipe Caps: A Detailed Overview

Materials Used in Pipe Caps: Choosing the Right One

Installation Methods for Pipe Caps

Maintenance and Inspection of Pipe Caps

Common Applications of Pipe Caps in Various Industries

Benefits of Using Pipe Caps for

Pipe Caps: The Ultimate Protection for Flange Joints

Table of Contents

- Introduction to Pipe Caps and Their Importance

- Types of Pipe Caps: A Detailed Overview

- Materials Used in Pipe Caps: Choosing the Right One

- Installation Methods for Pipe Caps

- Maintenance and Inspection of Pipe Caps

- Common Applications of Pipe Caps in Various Industries

- Benefits of Using Pipe Caps for Flange Joint Protection

- Conclusion: Ensuring Longevity and Safety with Pipe Caps

- FAQs: Your Questions Answered about Pipe Caps

Introduction to Pipe Caps and Their Importance

In the realm of **建筑和装饰材料** (building and decoration materials), pipe caps serve as essential components for protecting flange joints in piping systems. Flange joints are critical points where two pipe sections meet, often exposed to various environmental factors. Without adequate protection, these joints can deteriorate, leading to leaks, costly repairs, and safety hazards. This article delves into the significance of pipe caps, detailing their types, materials, applications, and maintenance considerations, ultimately reinforcing their role as a protective measure for flange joints.

Types of Pipe Caps: A Detailed Overview

Pipe caps, available in various shapes and sizes, can be categorized based on their design and application. Understanding these types is crucial for selecting the right cap for specific needs.

1. Standard Pipe Caps

Standard pipe caps are designed to fit over the end of a pipe, providing a tight seal. They come in various sizes and are commonly used in both residential and industrial applications.

2. Threaded Pipe Caps

Threaded pipe caps feature internal threads that allow them to screw onto the end of a threaded pipe. This design ensures a secure fit and is often utilized in high-pressure environments.

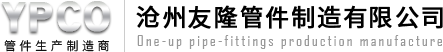

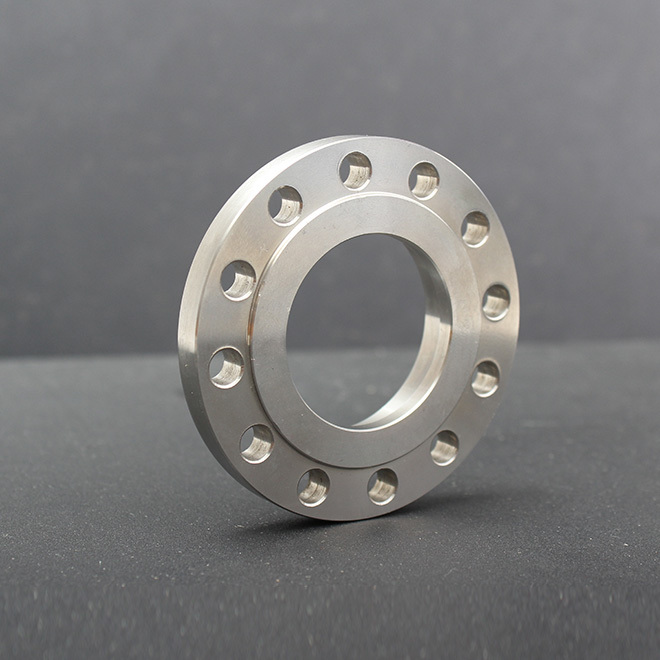

3. Blind Flange Caps

Blind flange caps are used to seal the end of a pipe and are often employed in systems that require a permanent closure. Their robust design provides excellent protection against external elements.

4. Welded Caps

Welded caps are permanently attached to pipes through welding. This method is ideal for high-pressure systems where a secure and leak-proof seal is paramount.

5. Push-On Caps

These caps are designed to be easily pushed onto the pipe end, making them suitable for temporary closures or applications where quick access is necessary.

Materials Used in Pipe Caps: Choosing the Right One

The material of a pipe cap significantly influences its performance, durability, and suitability for specific applications. Here are some common materials used in pipe caps:

1. Stainless Steel

Stainless steel pipe caps are known for their resistance to corrosion and high temperatures, making them ideal for harsh environments and industries such as oil and gas.

2. Carbon Steel

Carbon steel caps are robust and cost-effective, often used in standard piping applications. They provide excellent strength but may require protective coatings to prevent corrosion.

3. PVC (Polyvinyl Chloride)

PVC caps are lightweight and resistant to chemical corrosion, making them suitable for plumbing and drainage systems. They are easy to install and cost-effective.

4. Brass

Brass caps are commonly used in plumbing applications due to their resistance to corrosion and aesthetic appeal. They provide a reliable seal and can withstand moderate pressure.

5. HDPE (High-Density Polyethylene)

HDPE caps are flexible and resistant to chemical damage. They are often used in applications involving buried or underground pipes, offering durability and reliability.

Installation Methods for Pipe Caps

Proper installation of pipe caps is crucial for ensuring a secure fit and optimal protection for flange joints. Here are common methods for installing various types of pipe caps:

1. Installing Standard Pipe Caps

To install a standard pipe cap, simply push it onto the end of the pipe until it fits snugly. Ensure that the pipe is clean and free from debris to achieve a tight seal.

2. Threaded Pipe Cap Installation

For threaded pipe caps, align the cap with the threads on the pipe and screw it on clockwise. Use a pipe wrench for added torque, but avoid over-tightening to prevent damage.

3. Blind Flange Cap Installation

Blind flange caps require bolting onto the flange. Align the holes of the cap with those on the flange, insert bolts, and tighten evenly to create a secure seal.

4. Welded Cap Installation

Welded caps are attached using welding techniques. Ensure that the surfaces are clean, and use appropriate welding materials to create a strong, leak-proof bond.

5. Push-On Cap Installation

Simply push the cap onto the end of the pipe until it is firmly in place. This method allows for easy removal and reinstallation if necessary.

Maintenance and Inspection of Pipe Caps

Regular maintenance and inspection of pipe caps are essential for ensuring their longevity and effectiveness. Here are some best practices:

1. Scheduled Inspections

Conduct routine inspections to check for signs of wear, corrosion, or damage. Look for any leaks around the flange joints and assess the overall condition of the caps.

2. Cleaning

Keep the caps clean from dirt and debris, which can lead to corrosion over time. Use appropriate cleaning solutions that do not damage the materials.

3. Replacing Damaged Caps

If a cap shows signs of significant wear or damage, replace it immediately to avoid compromising the integrity of the flange joint.

4. Monitoring Environmental Conditions

Be aware of environmental factors such as humidity, temperature, and exposure to chemicals, which can affect the performance of the caps.

5. Documentation

Maintain records of inspections, maintenance performed, and any replacements made. This documentation helps track the condition of the piping system over time.

Common Applications of Pipe Caps in Various Industries

Pipe caps are used in a wide range of industries due to their versatility and protective features. Here are some common applications:

1. Oil and Gas Industry

In the oil and gas sector, pipe caps are critical for preventing leaks and protecting sensitive components from environmental damage during the transportation of hydrocarbons.

2. Water Treatment Facilities

Water treatment plants use pipe caps to seal pipes and prevent contamination. The durability of the caps ensures safe operation in the treatment process.

3. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, pipe caps provide protection for flange joints, maintaining system efficiency and preventing leaks.

4. Manufacturing Plants

Manufacturing facilities utilize pipe caps in various applications, including fluid transport and waste management, to ensure compliance with safety standards.

5. Residential Plumbing

In residential plumbing systems, pipe caps prevent leaks and provide a clean finish for exposed pipes, contributing to overall system integrity.

Benefits of Using Pipe Caps for Flange Joint Protection

Investing in high-quality pipe caps offers numerous advantages, enhancing the performance and safety of piping systems. Here are some key benefits:

1. Leak Prevention

Pipe caps effectively seal flange joints, preventing leaks that can lead to costly repairs and environmental hazards.

2. Corrosion Resistance

Using durable materials, such as stainless steel or PVC, helps resist corrosion, extending the lifespan of the piping system.

3. Easy Installation and Maintenance

Most pipe caps are designed for easy installation and maintenance, allowing for quick access to the piping system when necessary.

4. Cost-Effective Solution

Pipe caps offer a cost-effective way to protect flange joints, reducing the risk of extensive repairs and system downtime.

5. Improved Safety

By preventing leaks and ensuring the integrity of the piping system, pipe caps contribute to a safer working environment for employees.

Conclusion: Ensuring Longevity and Safety with Pipe Caps

In summary, pipe caps play an integral role in protecting flange joints across various industries. Their versatility, combined with the right materials and installation methods, ensures that piping systems operate efficiently and safely. By investing in high-quality pipe caps and adhering to maintenance best practices, industry professionals can significantly enhance the longevity and reliability of their piping systems.

FAQs: Your Questions Answered about Pipe Caps

1. What are pipe caps used for?

Pipe caps are used to seal the ends of pipes, preventing leaks and protecting flange joints from environmental damage.

2. How do I choose the right pipe cap material?

Consider the application, environmental conditions, and pressure requirements when selecting a pipe cap material.

3. Can pipe caps be reused?

Yes, depending on their condition, many pipe caps can be reused. However, inspect them for wear or damage before reinstallation.

4. How often should I inspect my pipe caps?

Regular inspections are recommended at least once a year or more frequently in harsh environments.

5. What happens if a pipe cap is damaged?

A damaged pipe cap should be replaced immediately to prevent leaks and maintain the integrity of the piping system.

pipe cap

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30