Why Choose Blind Flanges for Your Piping Needs? A Comprehensive Guide

2025-02-25

Why Choose Blind Flanges for Your Piping Needs?

When it comes to designing and maintaining efficient piping systems, the selection of the right components can make a significant difference. Among these components, **blind flanges** play a crucial role. In this article, we delve into the reasons why blind flanges are an excellent choice for your piping needs, their applications, benefits, and how t

Why Choose Blind Flanges for Your Piping Needs?

When it comes to designing and maintaining efficient piping systems, the selection of the right components can make a significant difference. Among these components, **blind flanges** play a crucial role. In this article, we delve into the reasons why blind flanges are an excellent choice for your piping needs, their applications, benefits, and how they can enhance the overall integrity of piping systems.

Table of Contents

- 1. Introduction to Blind Flanges

- 2. What Are Blind Flanges?

- 3. Benefits of Using Blind Flanges

- 4. Applications of Blind Flanges

- 5. Blind Flanges vs. Other Types of Flanges

- 6. Installation and Maintenance of Blind Flanges

- 7. Material Options for Blind Flanges

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Blind Flanges

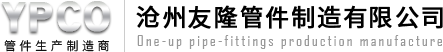

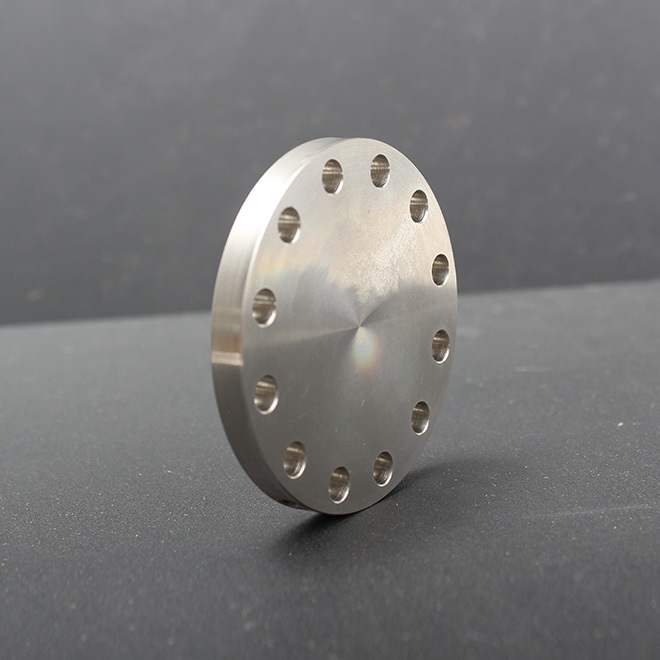

Blind flanges are integral components used in piping systems to seal the ends of pipes. They are typically circular discs devoid of any opening, which makes them ideal for closing off a pipeline. The usage of blind flanges is prevalent across various industries, including oil and gas, water treatment, and chemical manufacturing. These flanges are designed to withstand high pressure and temperature, ensuring the safety and reliability of the entire piping system.

2. What Are Blind Flanges?

Blind flanges are types of flanges that serve to close the open ends of a piping system. Unlike standard flanges that connect two pieces of pipe, blind flanges do not have a central opening. This unique design allows them to block off pipelines, prevent leaks, and isolate sections of the piping system for maintenance or safety reasons.

Blind flanges are available in various sizes, materials, and pressure ratings, making them suitable for a wide range of applications. They can be manufactured from materials such as carbon steel, stainless steel, and alloy steel, which provide durability and resistance to corrosion.

3. Benefits of Using Blind Flanges

The benefits of incorporating blind flanges into your piping systems are numerous. Here are some key advantages:

3.1 Enhanced Safety

One of the primary benefits of using blind flanges is the enhanced safety they provide. By sealing off pipe ends, blind flanges prevent the accidental release of hazardous substances, thereby reducing the risk of spills, leaks, or explosions.

3.2 Cost-Effectiveness

Blind flanges are a cost-effective solution for closing piping ends. They eliminate the need for additional fittings or modifications, resulting in significant savings on materials and labor during installation and maintenance.

3.3 Simplified Maintenance

With blind flanges, maintenance becomes easier. They allow for the isolation of specific sections of a piping system, enabling maintenance work without needing to shut down the entire system. This feature minimizes downtime and enhances operational efficiency.

3.4 Versatility

Blind flanges are versatile components that can be used in various applications, from water treatment plants to chemical processing facilities. Their adaptability to different conditions makes them a preferred choice for many engineers and designers.

4. Applications of Blind Flanges

Blind flanges find applications across numerous industries due to their unique characteristics. Here are some common uses:

4.1 Oil and Gas Industry

In the oil and gas sector, blind flanges are used to seal off pipe ends during temporary shutdowns or maintenance. They ensure that hazardous materials remain contained, maintaining safety and compliance with regulations.

4.2 Water Treatment

Water treatment facilities utilize blind flanges to isolate sections of piping during maintenance and repairs. Their ability to withstand high pressures makes them suitable for handling various water types and conditions.

4.3 Chemical Manufacturing

In chemical manufacturing, blind flanges are essential for managing corrosive substances. Their robust materials provide the necessary resistance to caustic chemicals, ensuring system integrity.

4.4 Power Generation

Power plants often use blind flanges in steam systems to prevent leaks and maintain high-pressure systems. Their reliability ensures the smooth operation of critical processes.

5. Blind Flanges vs. Other Types of Flanges

When considering piping components, it’s essential to understand how blind flanges compare to other types of flanges.

5.1 Blind Flanges vs. Welded Flanges

Welded flanges are often used when a permanent connection is required. Unlike blind flanges, welded flanges involve a joint that permanently attaches to the pipe, which may complicate future maintenance. Blind flanges offer more flexibility for temporary closures or maintenance needs.

5.2 Blind Flanges vs. Slip-On Flanges

Slip-on flanges are designed to slide over the pipe end before being welded into place. While they are useful for connecting two pipe segments, they do not provide the same level of isolation as blind flanges, making blind flanges a superior choice for sealing off piping ends.

5.3 Blind Flanges vs. Socket Weld Flanges

Socket weld flanges allow for easy assembly and disassembly but are not designed for permanent closure. Blind flanges provide a more secure solution for sealing pipe ends, ensuring that no fluid escapes.

6. Installation and Maintenance of Blind Flanges

Proper installation and maintenance of blind flanges are crucial for ensuring their effectiveness and longevity.

6.1 Installation Guidelines

To install blind flanges correctly, follow these steps:

- **Ensure Clean Surfaces**: Both the flange and the pipe ends should be clean and free of debris to ensure a proper seal.

- **Align Flanges**: Proper alignment is critical to prevent leaks. Ensure that the bolt holes line up correctly.

- **Use the Right Gaskets**: Select appropriate gaskets to provide a tight seal and prevent leaks.

- **Tighten Bolts Evenly**: Use a torque wrench to tighten the bolts evenly, following the recommended torque specifications.

6.2 Maintenance Practices

Regular inspection and maintenance of blind flanges can prevent potential issues. Here are some best practices:

- **Routine Inspections**: Regularly check for signs of corrosion, wear, or leaks.

- **Replace Damaged Flanges**: If a blind flange shows signs of damage, replace it immediately to maintain the system’s integrity.

- **Monitor Pressure Levels**: Ensure that pressure levels remain within acceptable limits to reduce stress on the flanges.

7. Material Options for Blind Flanges

The choice of material for blind flanges significantly affects their performance and suitability for specific applications.

7.1 Carbon Steel

Carbon steel is one of the most commonly used materials for blind flanges due to its strength and durability. It is ideal for general-purpose applications but may require coatings for environments prone to corrosion.

7.2 Stainless Steel

For applications involving corrosive substances, **stainless steel blind flanges** are preferable. Their resistance to corrosion and rust makes them suitable for water treatment and chemical processes.

7.3 Alloy Steel

Alloy steel offers enhanced strength and resistance to extreme temperatures, making it ideal for high-pressure applications, such as in the oil and gas industry.

8. Frequently Asked Questions

8.1 What is the purpose of a blind flange?

Blind flanges are used to seal the ends of pipes, preventing leaks and allowing for maintenance of the piping system.

8.2 How do you install a blind flange?

To install a blind flange, ensure clean surfaces, align the flanges, use the correct gaskets, and tighten the bolts evenly.

8.3 What materials are commonly used for blind flanges?

Common materials include carbon steel, stainless steel, and alloy steel, each selected based on the specific application and environmental conditions.

8.4 Can blind flanges be reused?

Yes, blind flanges can be reused if they are in good condition. However, it’s essential to inspect them for signs of wear or damage before reuse.

8.5 What industries commonly use blind flanges?

Blind flanges are used across various industries, including oil and gas, water treatment, chemical manufacturing, and power generation.

9. Conclusion

Blind flanges are indispensable components in piping systems, offering safety, cost-effectiveness, and versatility. Their ability to seal off pipe ends makes them a top choice for various applications across numerous industries. By selecting the right material and ensuring proper installation and maintenance, you can enhance the integrity and performance of your piping systems. In an industry where safety and efficiency are paramount, choosing blind flanges is a decision that cannot be overlooked.

blind flange

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30