Exploring Different Materials Used for SO Flanges: A Comprehensive Guide

2025-02-07

Exploring Different Materials Used for SO Flanges

Table of Contents

1. Introduction to SO Flanges

2. Importance of Choosing the Right Material for SO Flanges

3. Types of Materials Used for SO Flanges

3.1 Stainless Steel Flanges

3.2 Carbon Steel Flanges

3.3 Alloy Steel Flanges

3.4 Ductile Iron Flanges

3.5 Plastic Flan

Exploring Different Materials Used for SO Flanges

Table of Contents

- 1. Introduction to SO Flanges

- 2. Importance of Choosing the Right Material for SO Flanges

- 3. Types of Materials Used for SO Flanges

- 3.1 Stainless Steel Flanges

- 3.2 Carbon Steel Flanges

- 3.3 Alloy Steel Flanges

- 3.4 Ductile Iron Flanges

- 3.5 Plastic Flanges

- 4. Applications of SO Flanges Based on Material

- 5. Maintenance Tips for Different Flange Materials

- 6. Material Comparison: Which is Best for Your Needs?

- 7. Frequently Asked Questions

- 8. Conclusion

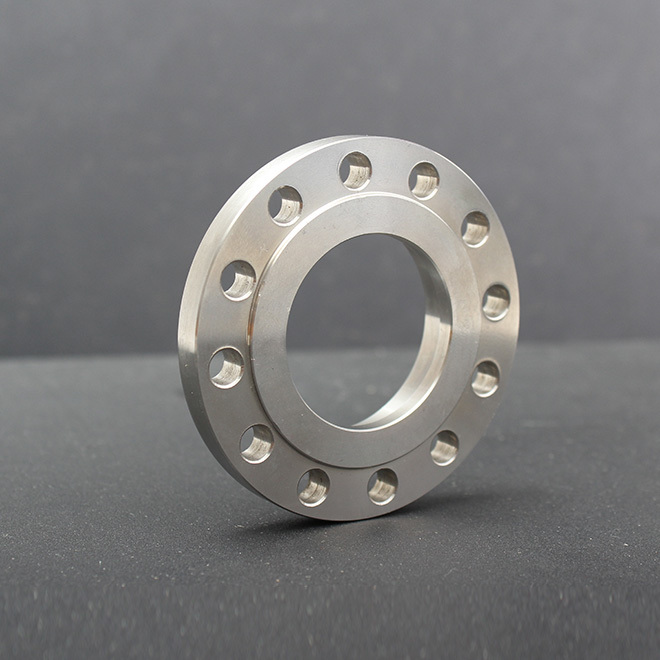

1. Introduction to SO Flanges

SO flanges, or slip-on flanges, are crucial components in piping systems, designed to provide a reliable connection between two segments of pipe. They are characterized by their simple installation process and versatility, making them a popular choice across various industries. In this article, we will explore the different materials used for SO flanges, how each material affects performance, and the best practices for selecting the right flange for your application.

2. Importance of Choosing the Right Material for SO Flanges

Selecting the appropriate material for SO flanges is vital for several reasons. The material influences the flange's durability, resistance to corrosion, ability to withstand high temperatures, and overall mechanical properties. An ill-suited material can lead to failures such as leaks or structural weaknesses, resulting in costly repairs and safety hazards. Therefore, understanding the properties of each material is essential for ensuring the longevity and functionality of your piping system.

3. Types of Materials Used for SO Flanges

In the world of SO flanges, there are several key materials that stand out due to their unique properties and applications. Below, we will delve into the most commonly used materials.

3.1 Stainless Steel Flanges

Stainless steel is one of the most popular materials for SO flanges, known for its excellent corrosion resistance and mechanical strength. It is an ideal choice for environments that expose the flanges to moisture, chemicals, or extreme temperatures. Stainless steel flanges are often used in food processing, chemical plants, and marine applications.

**Advantages:**

- High resistance to corrosion and oxidation

- Good mechanical strength

- Easy to clean and maintain

- Suitable for a wide range of temperatures

**Disadvantages:**

- Higher cost compared to other materials

- Susceptible to galling under certain conditions

3.2 Carbon Steel Flanges

Carbon steel is another common material used for SO flanges, particularly in industrial applications. Its strength and affordability make it a popular choice, although it does not possess the same level of corrosion resistance as stainless steel.

**Advantages:**

- Cost-effective

- High strength and durability

- Good performance under high pressure

**Disadvantages:**

- Prone to rust and corrosion

- Requires protective coatings for longevity

3.3 Alloy Steel Flanges

Alloy steel flanges are made from a combination of carbon steel and various alloying elements such as chromium, molybdenum, and nickel. These additions enhance the material's strength, toughness, and corrosion resistance, making alloy steel flanges suitable for extreme environments.

**Advantages:**

- Enhanced strength and durability

- Improved resistance to heat and corrosion

- Suitable for high-stress applications

**Disadvantages:**

- More expensive than carbon steel

- Requires specialized welding techniques

3.4 Ductile Iron Flanges

Ductile iron flanges are made from a type of cast iron that exhibits increased ductility and toughness. They are often chosen for their ability to withstand heavy loads and stresses, making them suitable for municipal and industrial applications.

**Advantages:**

- High load-bearing capacity

- Excellent toughness and ductility

- Good resistance to wear and abrasion

**Disadvantages:**

- Heavier than other materials

- Limited corrosion resistance compared to stainless steel

3.5 Plastic Flanges

Plastic flanges, such as those made from PVC or CPVC, are lightweight and resistant to corrosion. They are commonly used in chemical processing, water treatment, and other applications where corrosion resistance is essential.

**Advantages:**

- Lightweight and easy to handle

- Excellent resistance to corrosion and chemicals

- Cost-effective in certain applications

**Disadvantages:**

- Limited temperature and pressure capabilities

- Not suitable for high-stress applications

4. Applications of SO Flanges Based on Material

Different materials used for SO flanges cater to various applications. Understanding the specific requirements of each application will help you choose the right flange material.

- **Stainless Steel Flanges**: Commonly used in food and beverage processing, pharmaceuticals, and marine environments due to their hygienic properties and corrosion resistance.

- **Carbon Steel Flanges**: Widely utilized in oil and gas pipelines, chemical plants, and power generation facilities where strength is paramount.

- **Alloy Steel Flanges**: Ideal for high-pressure applications, such as those found in petrochemical and nuclear power plants.

- **Ductile Iron Flanges**: Often used in municipal water systems and wastewater treatment plants due to their robust nature.

- **Plastic Flanges**: Frequently found in chemical processing and irrigation systems where corrosion resistance is critical.

5. Maintenance Tips for Different Flange Materials

Maintaining SO flanges is crucial for ensuring their longevity and performance. Here are some tailored maintenance tips based on material type:

- **Stainless Steel**: Regularly clean flanges with mild soap and water to prevent buildup and ensure cleanliness, which is essential in food processing applications.

- **Carbon Steel**: Inspect for signs of rust and apply protective coatings to prevent corrosion. Regular maintenance can extend the lifespan of carbon steel flanges significantly.

- **Alloy Steel**: Inspect welds and joints frequently, as they may experience fatigue under high-stress conditions. Use appropriate protective measures to combat corrosion.

- **Ductile Iron**: Check for signs of wear and deformation. Proper sealing and regular cleaning will help maintain their integrity.

- **Plastic**: Inspect for cracks or signs of stress, especially when subjected to high temperatures. Avoid exposure to harmful chemicals that can degrade the material.

6. Material Comparison: Which is Best for Your Needs?

When choosing the right material for SO flanges, it's essential to consider factors such as cost, environment, pressure, and temperature requirements. A quick comparison can help you make an informed decision:

| Material Type | Cost | Corrosion Resistance | Temperature Tolerance | Strength |

|---------------------|--------|----------------------|-----------------------|---------------|

| Stainless Steel | High | Excellent | High | Moderate |

| Carbon Steel | Low | Moderate | Moderate | High |

| Alloy Steel | High | Good | Very High | Very High |

| Ductile Iron | Moderate| Moderate | Moderate | Very High |

| Plastic | Low | Excellent | Low | Low |

Selecting the right flange material ultimately depends on the specific requirements of your application.

7. Frequently Asked Questions

What are SO flanges used for?

SO flanges are primarily used to connect pipes in a variety of industries, including oil and gas, water treatment, and food processing.

What is the difference between SO flanges and other types of flanges?

SO flanges are slip-on flanges that slide over the pipe, while other types, like weld neck flanges, are welded onto the pipe. This makes SO flanges easier to install.

How do I determine the right flange material for my project?

Consider factors such as the environment, pressure, temperature, and cost. Stainless steel is ideal for corrosive environments, while carbon steel is suitable for general industrial applications.

Can plastic flanges be used in high-temperature applications?

Generally, plastic flanges have limited temperature tolerance and are not recommended for high-temperature applications.

How often should I inspect my flanges?

Regular inspections should be conducted at least annually, though more frequent checks may be necessary in high-pressure or corrosive environments.

8. Conclusion

In conclusion, understanding the various materials used for SO flanges is essential for ensuring the longevity and effectiveness of your piping systems. Each material has its distinct advantages and disadvantages, making it crucial to consider your specific application requirements. Stainless steel, carbon steel, alloy steel, ductile iron, and plastic all have unique properties that cater to different scenarios. By making informed decisions based on this comprehensive guide, you can optimize your flange selection, ensuring reliability and performance in your projects.

so flange

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

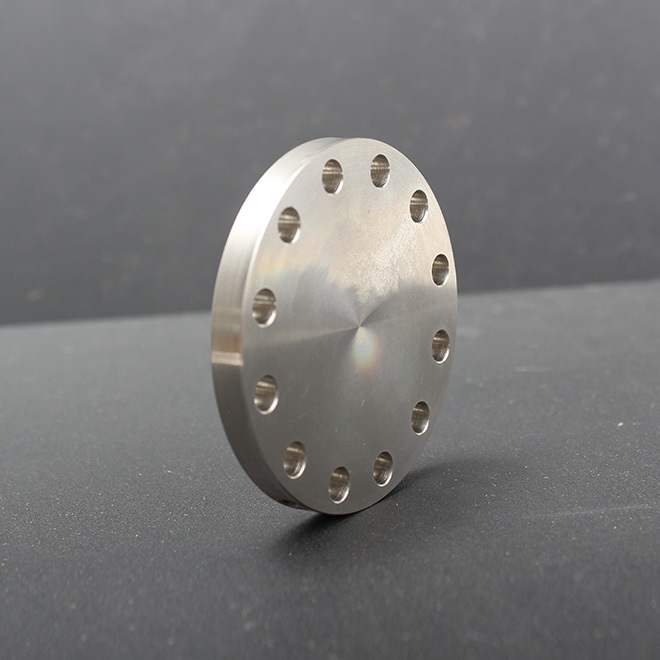

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30