Unlocking the Strength of Carbon Steel Buttweld Pipe Fittings: The Ultimate Guide

2024-10-12

Unlocking the Strength of Carbon Steel Buttweld Pipe Fittings

Table of Contents

1. Introduction to Carbon Steel Buttweld Pipe Fittings

2. Why Choose Carbon Steel? Understanding Its Strength

3. Types of Carbon Steel Buttweld Pipe Fittings

3.1 Elbows

3.2 Tees

3.3 Reducers

3.4 Caps

4. Applications of Carbon Steel Buttweld Pipe Fittings

5. Advantages of Using Carbon Steel Buttweld Pipe Fittings

6. Ins

Unlocking the Strength of Carbon Steel Buttweld Pipe Fittings

Table of Contents

1. Introduction to Carbon Steel Buttweld Pipe Fittings

2. Why Choose Carbon Steel? Understanding Its Strength

3. Types of Carbon Steel Buttweld Pipe Fittings

3.1 Elbows

3.2 Tees

3.3 Reducers

3.4 Caps

4. Applications of Carbon Steel Buttweld Pipe Fittings

5. Advantages of Using Carbon Steel Buttweld Pipe Fittings

6. Installation Best Practices

7. Maintenance and Care for Longevity

8. FAQs about Carbon Steel Buttweld Pipe Fittings

9. Conclusion

1. Introduction to Carbon Steel Buttweld Pipe Fittings

Carbon steel buttweld pipe fittings are essential components in piping systems, known for their ability to withstand high pressures and temperatures. These fittings are used to connect pipes of various sizes, allowing for seamless transitions and changes in direction. In industries ranging from oil and gas to construction, the demand for robust and reliable pipe fittings is paramount. This article will explore the unique attributes of carbon steel buttweld pipe fittings, highlighting their strength and versatility.

2. Why Choose Carbon Steel? Understanding Its Strength

Carbon steel is an alloy consisting mainly of iron and carbon, making it stronger and more durable than many other materials. The properties of carbon steel contribute to its widespread use in various applications. The strength of carbon steel can be attributed to several factors:

- **High Tensile Strength**: Carbon steel can endure significant stress without deforming, making it ideal for high-pressure applications.

- **Weldability**: The ability to weld carbon steel fittings ensures a strong, permanent bond that can withstand harsh conditions.

- **Cost-Effectiveness**: Compared to other materials like stainless steel or plastic, carbon steel is often less expensive, making it a budget-friendly option for large projects.

3. Types of Carbon Steel Buttweld Pipe Fittings

Understanding the different types of carbon steel buttweld fittings is crucial for selecting the right component for your specific application. Each type serves a unique purpose in pipe systems.

3.1 Elbows

Elbows are utilized to change the direction of the piping. They typically come in 45-degree and 90-degree angles, allowing for flexible routing of pipes.

3.2 Tees

Tees are used to connect three pipes, allowing for branching in a piping system. They are available in various sizes to accommodate different pipe diameters.

3.3 Reducers

Reducers are designed to connect pipes of different diameters. They enable a smooth transition from a larger pipe to a smaller one, minimizing turbulence and enhancing flow efficiency.

3.4 Caps

Caps are used to close the end of a pipe. They are essential in systems where pipes may need to be sealed for maintenance or future expansion.

4. Applications of Carbon Steel Buttweld Pipe Fittings

The versatility of carbon steel buttweld pipe fittings makes them suitable for a wide range of applications, including:

- **Oil and Gas Industry**: High-pressure pipelines require robust materials to ensure safety and reliability.

- **Water Supply Systems**: Carbon steel fittings are often utilized in municipal water systems to provide longevity and strength.

- **Construction Projects**: Many structural applications in buildings rely on the durability of carbon steel fittings.

- **HVAC Systems**: These fittings are commonly used in heating and cooling systems for their thermal resistance.

5. Advantages of Using Carbon Steel Buttweld Pipe Fittings

Selecting carbon steel buttweld pipe fittings offers numerous advantages, such as:

- **Durability**: Carbon steel fittings are designed to last, resisting wear and tear even in demanding environments.

- **Corrosion Resistance**: While not as resistant as stainless steel, certain carbon steel fittings are treated to withstand corrosion, enhancing their lifespan.

- **Versatile Design Options**: Available in various shapes and sizes, carbon steel buttweld fittings can be tailored to meet diverse project requirements.

- **Ease of Maintenance**: Regular inspections and maintenance ensure that these fittings remain functional and reliable over time.

6. Installation Best Practices

Proper installation of carbon steel buttweld pipe fittings is critical for maintaining system integrity. Here are some best practices to follow:

- **Preparation**: Ensure all surfaces are clean and free from debris before welding.

- **Welding Techniques**: Utilize the appropriate welding technique for carbon steel to ensure a strong bond.

- **Inspecting Joints**: After installation, inspect all joints and fittings for leaks or weaknesses.

- **Follow Manufacturer Guidelines**: Always adhere to specific guidelines provided by manufacturers for optimal results.

7. Maintenance and Care for Longevity

To extend the life of carbon steel buttweld pipe fittings, regular maintenance is essential. Consider the following:

- **Routine Inspections**: Regularly check for signs of wear, corrosion, or leaks.

- **Cleaning**: Keep fittings clean to prevent the buildup of dirt and debris, which can lead to corrosion.

- **Protective Coatings**: Apply protective coatings to enhance corrosion resistance, especially in harsh environments.

8. FAQs about Carbon Steel Buttweld Pipe Fittings

What is the difference between carbon steel and stainless steel fittings?

Carbon steel fittings are generally stronger and more cost-effective, whereas stainless steel fittings offer superior corrosion resistance.

Can carbon steel buttweld fittings be used in high-temperature applications?

Yes, carbon steel buttweld fittings are suitable for high-temperature applications, provided they are designed for such conditions.

How do I know which type of fitting to use?

The type of fitting needed depends on the specific requirements of your piping system, including the direction of flow and pipe sizes.

Are carbon steel fittings suitable for outdoor use?

Yes, but they should be treated with protective coatings to prevent rust and corrosion when exposed to the elements.

What is the lifespan of carbon steel buttweld pipe fittings?

With proper installation and maintenance, carbon steel buttweld pipe fittings can last several decades.

9. Conclusion

Carbon steel buttweld pipe fittings stand out as an exceptional choice for a variety of applications due to their unmatched strength, durability, and cost-effectiveness. Whether you are involved in oil and gas, construction, or municipal projects, understanding the unique attributes and best practices associated with these fittings is essential for achieving optimal performance. By following the guidelines outlined in this article, you can ensure that your piping systems remain robust, reliable, and efficient for years to come. Embrace the strength of carbon steel buttweld pipe fittings in your next project, and experience the difference in quality and performance.

carbon steel buttweld pipe fittings

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

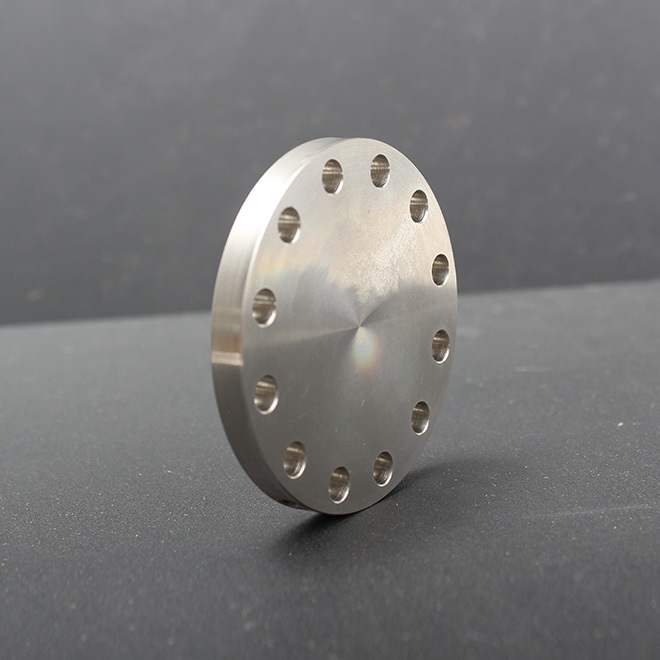

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30