Understanding the Role and Applications of 90 Degree Elbows in Piping Systems

2024-09-24

When it comes to piping systems in construction and decorative materials, the 90 degree elbow is an essential component that facilitates the direction of fluid flow. These fittings allow for seamless transitions in a piping system, making them indispensable in various applications, from residential plumbing to complex industrial setups.

A 90 degree elbow is designed to change the direction of flow

When it comes to piping systems in construction and decorative materials, the 90 degree elbow is an essential component that facilitates the direction of fluid flow. These fittings allow for seamless transitions in a piping system, making them indispensable in various applications, from residential plumbing to complex industrial setups.

A 90 degree elbow is designed to change the direction of flow by 90 degrees. This is particularly useful in scenarios where space constraints or design specifications necessitate an alteration in the pipeline's trajectory. By directing the flow efficiently, 90 degree elbows help reduce the possibility of blockages and improve overall system performance.

One of the primary advantages of using 90 degree elbows is their ability to minimize turbulence in the fluid flow. Turbulence can lead to increased wear and tear on pipes, so using a fitting that smoothly redirects the flow can extend the life of the piping system. Moreover, 90 degree elbows come in various materials, such as PVC, copper, and stainless steel, allowing professionals to select the best option based on the specific requirements of their projects.

In the context of installation, the proper alignment of 90 degree elbows is crucial. Misalignment can lead to increased pressure on the joints and potential leaks. Therefore, it's important for professionals to ensure precise installation using appropriate techniques and tools. Additionally, understanding the specifications of the elbow fitting, including its diameter and wall thickness, is vital for optimal performance.

Furthermore, the selection of a 90 degree elbow should consider factors such as the type of fluid being transported, temperature variations, and pressure conditions. For example, in applications involving corrosive substances, using a material resistant to such chemicals will enhance longevity and reliability.

Another critical consideration is adherence to industry standards and regulations. Compliance ensures that the piping system is safe and efficient. Professionals should always stay updated on the latest guidelines pertaining to piping materials and installation practices.

In conclusion, 90 degree elbows play a pivotal role in the efficiency and effectiveness of piping systems within the construction and decorative materials industry. By understanding their applications, advantages, and installation practices, professionals can make informed decisions that enhance their projects and meet client expectations. Emphasizing quality and compliance will further ensure that the use of 90 degree elbows contributes positively to the overall success of the piping systems being constructed.

A 90 degree elbow is designed to change the direction of flow by 90 degrees. This is particularly useful in scenarios where space constraints or design specifications necessitate an alteration in the pipeline's trajectory. By directing the flow efficiently, 90 degree elbows help reduce the possibility of blockages and improve overall system performance.

One of the primary advantages of using 90 degree elbows is their ability to minimize turbulence in the fluid flow. Turbulence can lead to increased wear and tear on pipes, so using a fitting that smoothly redirects the flow can extend the life of the piping system. Moreover, 90 degree elbows come in various materials, such as PVC, copper, and stainless steel, allowing professionals to select the best option based on the specific requirements of their projects.

In the context of installation, the proper alignment of 90 degree elbows is crucial. Misalignment can lead to increased pressure on the joints and potential leaks. Therefore, it's important for professionals to ensure precise installation using appropriate techniques and tools. Additionally, understanding the specifications of the elbow fitting, including its diameter and wall thickness, is vital for optimal performance.

Furthermore, the selection of a 90 degree elbow should consider factors such as the type of fluid being transported, temperature variations, and pressure conditions. For example, in applications involving corrosive substances, using a material resistant to such chemicals will enhance longevity and reliability.

Another critical consideration is adherence to industry standards and regulations. Compliance ensures that the piping system is safe and efficient. Professionals should always stay updated on the latest guidelines pertaining to piping materials and installation practices.

In conclusion, 90 degree elbows play a pivotal role in the efficiency and effectiveness of piping systems within the construction and decorative materials industry. By understanding their applications, advantages, and installation practices, professionals can make informed decisions that enhance their projects and meet client expectations. Emphasizing quality and compliance will further ensure that the use of 90 degree elbows contributes positively to the overall success of the piping systems being constructed.

90 degree elbow

RELATED NEWS

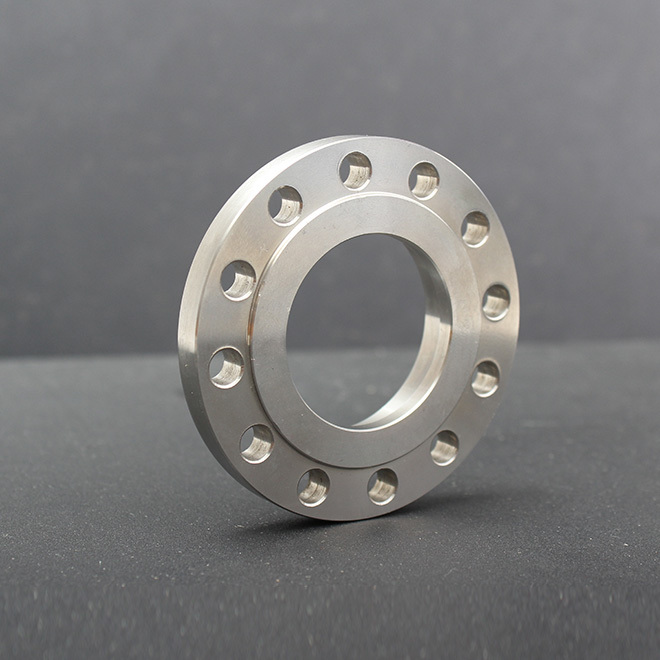

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

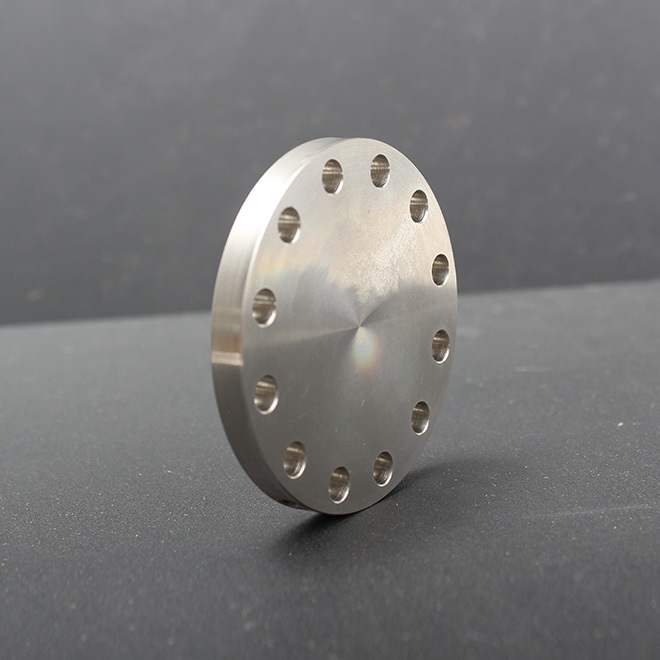

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30