Unlocking the Strength: Weld Neck Flanges in Modern Construction

2024-03-13

# Introduction

In the dynamic world of construction and infrastructure development, the demand for high-quality materials and components is ever-present. One such critical element that plays a significant role in modern construction projects is the weld neck flange. These essential fittings are crucial for ensuring the structural integrity and durability of pipelines, industrial systems, and vario

# Introduction

In the dynamic world of construction and infrastructure development, the demand for high-quality materials and components is ever-present. One such critical element that plays a significant role in modern construction projects is the weld neck flange. These essential fittings are crucial for ensuring the structural integrity and durability of pipelines, industrial systems, and various other applications. In this article, we will delve into the world of weld neck flanges, exploring their strengths, benefits, and the crucial role they play in today's construction industry.

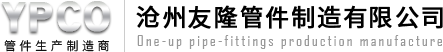

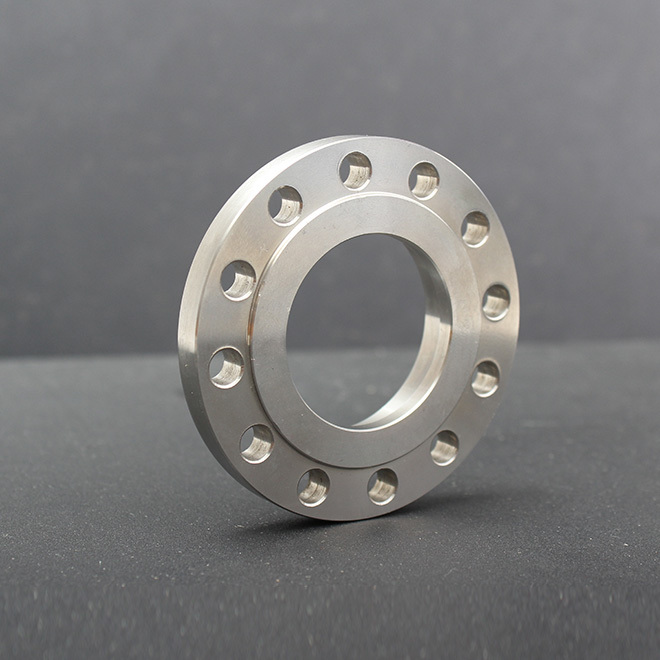

## What are Weld Neck Flanges?

Weld neck flanges are a type of flange that is specially designed to be welded to a piping system. These flanges are attached to the pipe by welding the neck to the pipe, providing a strong and durable connection. Weld neck flanges are widely used in high-pressure and high-temperature applications, where reliability and structural integrity are paramount.

### The Strengths of Weld Neck Flanges

One of the key strengths of weld neck flanges is their ability to provide a strong and leak-proof connection between pipes. The welding process creates a tight seal, ensuring that no fluids or gases can escape from the system. Additionally, weld neck flanges are designed to withstand high pressures and temperatures, making them ideal for use in challenging environments.

#### Benefits of Weld Neck Flanges in Modern Construction

In modern construction projects, weld neck flanges offer a range of benefits that contribute to the overall efficiency and durability of the system. These benefits include:

1. Enhanced Structural Integrity: Weld neck flanges provide a secure and reliable connection between pipes, ensuring the structural integrity of the system.

2. Leak-Proof Design: The welded connection of weld neck flanges prevents leaks and ensures the efficient flow of fluids or gases.

3. High Pressure and Temperature Resistance: Weld neck flanges are designed to withstand extreme pressures and temperatures, making them suitable for a wide range of applications.

4. Longevity and Durability: The robust construction of weld neck flanges ensures long-term performance and durability, reducing the need for frequent maintenance or replacement.

##### Applications of Weld Neck Flanges

Weld neck flanges find extensive use in various industries and applications, including:

- Oil and Gas Industry

- Petrochemical Plants

- Power Generation Facilities

- Chemical Processing Plants

- Water Treatment Systems

- HVAC Systems

###### Frequently Asked Questions (FAQs)

1. What materials are weld neck flanges made of?

Weld neck flanges are typically made of materials such as carbon steel, stainless steel, and alloy steel, depending on the application requirements.

2. How are weld neck flanges installed?

Weld neck flanges are welded to the pipe using a specialized welding process, ensuring a secure and leak-proof connection.

3. What are the standard sizes of weld neck flanges?

Weld neck flanges come in a range of sizes, from half-inch to several feet in diameter, depending on the pipe dimensions and application requirements.

4. Are weld neck flanges suitable for high-temperature applications?

Yes, weld neck flanges are designed to withstand high temperatures and pressures, making them ideal for use in demanding industrial environments.

5. Can weld neck flanges be customized for specific applications?

Yes, weld neck flanges can be customized in terms of material, size, and design to meet the specific requirements of the application.

# Conclusion

In conclusion, weld neck flanges are an indispensable component in modern construction projects, offering a combination of strength, durability, and reliability. Their ability to provide a secure and leak-proof connection between pipes makes them essential for ensuring the smooth operation of pipelines, industrial systems, and various other applications. By understanding the strengths and benefits of weld neck flanges, construction professionals can make informed decisions to enhance the efficiency and longevity of their projects.

In the dynamic world of construction and infrastructure development, the demand for high-quality materials and components is ever-present. One such critical element that plays a significant role in modern construction projects is the weld neck flange. These essential fittings are crucial for ensuring the structural integrity and durability of pipelines, industrial systems, and various other applications. In this article, we will delve into the world of weld neck flanges, exploring their strengths, benefits, and the crucial role they play in today's construction industry.

## What are Weld Neck Flanges?

Weld neck flanges are a type of flange that is specially designed to be welded to a piping system. These flanges are attached to the pipe by welding the neck to the pipe, providing a strong and durable connection. Weld neck flanges are widely used in high-pressure and high-temperature applications, where reliability and structural integrity are paramount.

### The Strengths of Weld Neck Flanges

One of the key strengths of weld neck flanges is their ability to provide a strong and leak-proof connection between pipes. The welding process creates a tight seal, ensuring that no fluids or gases can escape from the system. Additionally, weld neck flanges are designed to withstand high pressures and temperatures, making them ideal for use in challenging environments.

#### Benefits of Weld Neck Flanges in Modern Construction

In modern construction projects, weld neck flanges offer a range of benefits that contribute to the overall efficiency and durability of the system. These benefits include:

1. Enhanced Structural Integrity: Weld neck flanges provide a secure and reliable connection between pipes, ensuring the structural integrity of the system.

2. Leak-Proof Design: The welded connection of weld neck flanges prevents leaks and ensures the efficient flow of fluids or gases.

3. High Pressure and Temperature Resistance: Weld neck flanges are designed to withstand extreme pressures and temperatures, making them suitable for a wide range of applications.

4. Longevity and Durability: The robust construction of weld neck flanges ensures long-term performance and durability, reducing the need for frequent maintenance or replacement.

##### Applications of Weld Neck Flanges

Weld neck flanges find extensive use in various industries and applications, including:

- Oil and Gas Industry

- Petrochemical Plants

- Power Generation Facilities

- Chemical Processing Plants

- Water Treatment Systems

- HVAC Systems

###### Frequently Asked Questions (FAQs)

1. What materials are weld neck flanges made of?

Weld neck flanges are typically made of materials such as carbon steel, stainless steel, and alloy steel, depending on the application requirements.

2. How are weld neck flanges installed?

Weld neck flanges are welded to the pipe using a specialized welding process, ensuring a secure and leak-proof connection.

3. What are the standard sizes of weld neck flanges?

Weld neck flanges come in a range of sizes, from half-inch to several feet in diameter, depending on the pipe dimensions and application requirements.

4. Are weld neck flanges suitable for high-temperature applications?

Yes, weld neck flanges are designed to withstand high temperatures and pressures, making them ideal for use in demanding industrial environments.

5. Can weld neck flanges be customized for specific applications?

Yes, weld neck flanges can be customized in terms of material, size, and design to meet the specific requirements of the application.

# Conclusion

In conclusion, weld neck flanges are an indispensable component in modern construction projects, offering a combination of strength, durability, and reliability. Their ability to provide a secure and leak-proof connection between pipes makes them essential for ensuring the smooth operation of pipelines, industrial systems, and various other applications. By understanding the strengths and benefits of weld neck flanges, construction professionals can make informed decisions to enhance the efficiency and longevity of their projects.

weld neck flange

RELATED NEWS

Understanding JIS 5K Flanges: A Key Component in Construction and Decoration

In the construction and decoration materials industry, particularly in piping systems, the JIS 5K flange stands out as a crucial component. These flanges are manufactured according to the Japanese Industrial Standard (JIS), ensuring quality and reliability in various applications. Understanding the specifications and benefits of JIS 5K flanges is essential for professionals in this field.

JIS 5K f

2025-04-05

Essential Features of Carbon Steel Blind Flanges You Should Know

Essential Features of Carbon Steel Blind Flanges You Should Know

Table of Contents

1. Introduction to Carbon Steel Blind Flanges

2. What Are Blind Flanges?

3. Benefits of Carbon Steel Blind Flanges

4. Key Features of Carbon Steel Blind Flanges

5. Applications of Carbon Steel Blind Flanges

6. Proper Installation and Maintenance

7. Choosing the Right Blind Flange for You

2025-04-02

Understanding Butt Welding Pipe Fittings: A Comprehensive Guide

Butt welding pipe fittings are crucial components in piping systems, widely used in various industries, including construction and decorative materials. These fittings are designed to connect two pipes by welding their ends together, creating a strong and reliable joint. This method is particularly favored for its ability to maintain the integrity and flow characteristics of the pipeline, making i

2025-03-30